|

Deutsch

|

Deutsch

ZAR4 - Variable Spur Gears

The ZAR4 software designs involute spur gears of any shape. Pitch curve of gear wheel 1 can be defined free. ZAR4 calculates pitch curve of gear wheel 2 (counterwheel) and involute teeth.

You can define pitch curve of driving gear wheel as ellipse, sine, sine-linear, polynomial function, polygone, eccentric circle.

Or you can freely define the pitch curve, by input of up to 10 mathematical formulas, that are valid for a specified section (0° .. 360°).

Or you can define up to 50 points on the pitch curve, and ZAR4 calculates the polynomial function through the points.

Or you can define up to 1000 points of the pitch curve as polyline. Or you can import a polyline as DXF file from CAD. Or import pitch curve positions via clipboard from MS Excel or another spread sheet software.

Pressure angle, number of teeth, and face width are entered then. The module changes with the pitch radius (mn = d/z). Or you set "mn=const", then module is constant and calculated from the perimeter of the pitch curve. Addendum and dedendum coefficients of tool can be selected from database. Total gear ratio can be 1 or 2 or 3 or more.

ZAR4 calculates center distance and pitch curve of the counter gear. Transmission ratio, speed and acceleration are displayed at diagrams.

Transmission ratio

Total transmission ratio (gear teeth ratio) can be 1 or 2, 3, 4 or higher.

Pitch curve

You can display pitch curves without involute teeth. This can create completely new gear geometries.

Animation

Animation allows you to discover meshing errors, when the gear rotates on the screen.

Strength calculation

ZAR4 calculates strength according to ISO 6336 or DIN 3390 by means of equivalent round gears.

Quick View

Quick View shows drawings, diagrams and tables altogether on one screen. Quick4 View in an ISO 7200 drawing frame.

CAD Interface

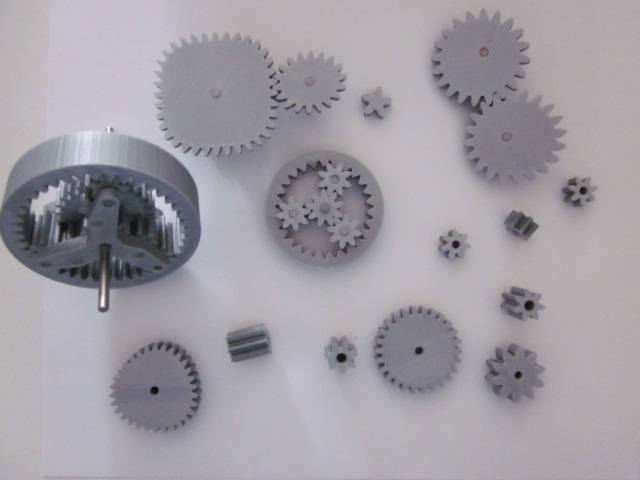

ZAR4 generates true scale drawings as DXF or IGES files to be used with your CAD system.STL Interface

ZAR4 generates STL files of the noncircular gear wheels to be printed on 3D printer.